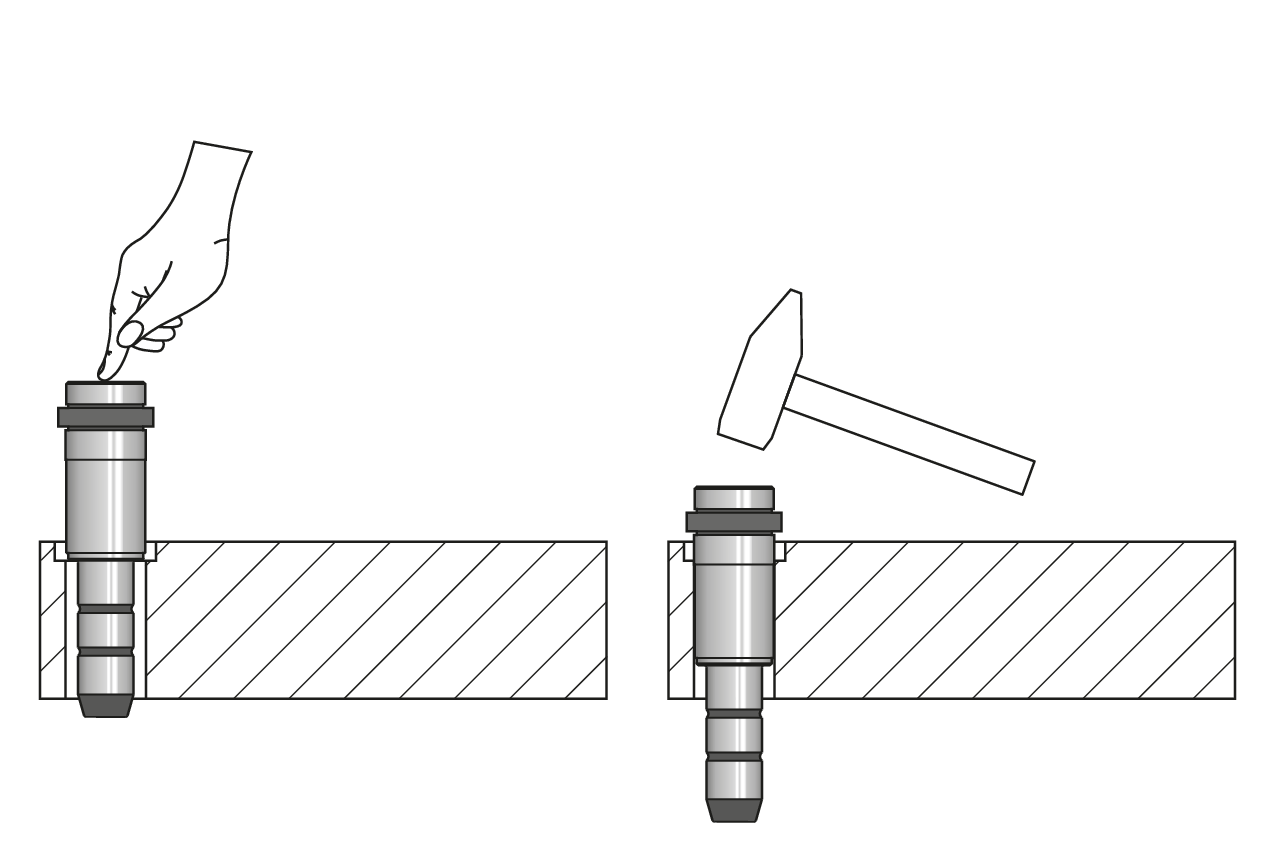

Installation example – Sectional view

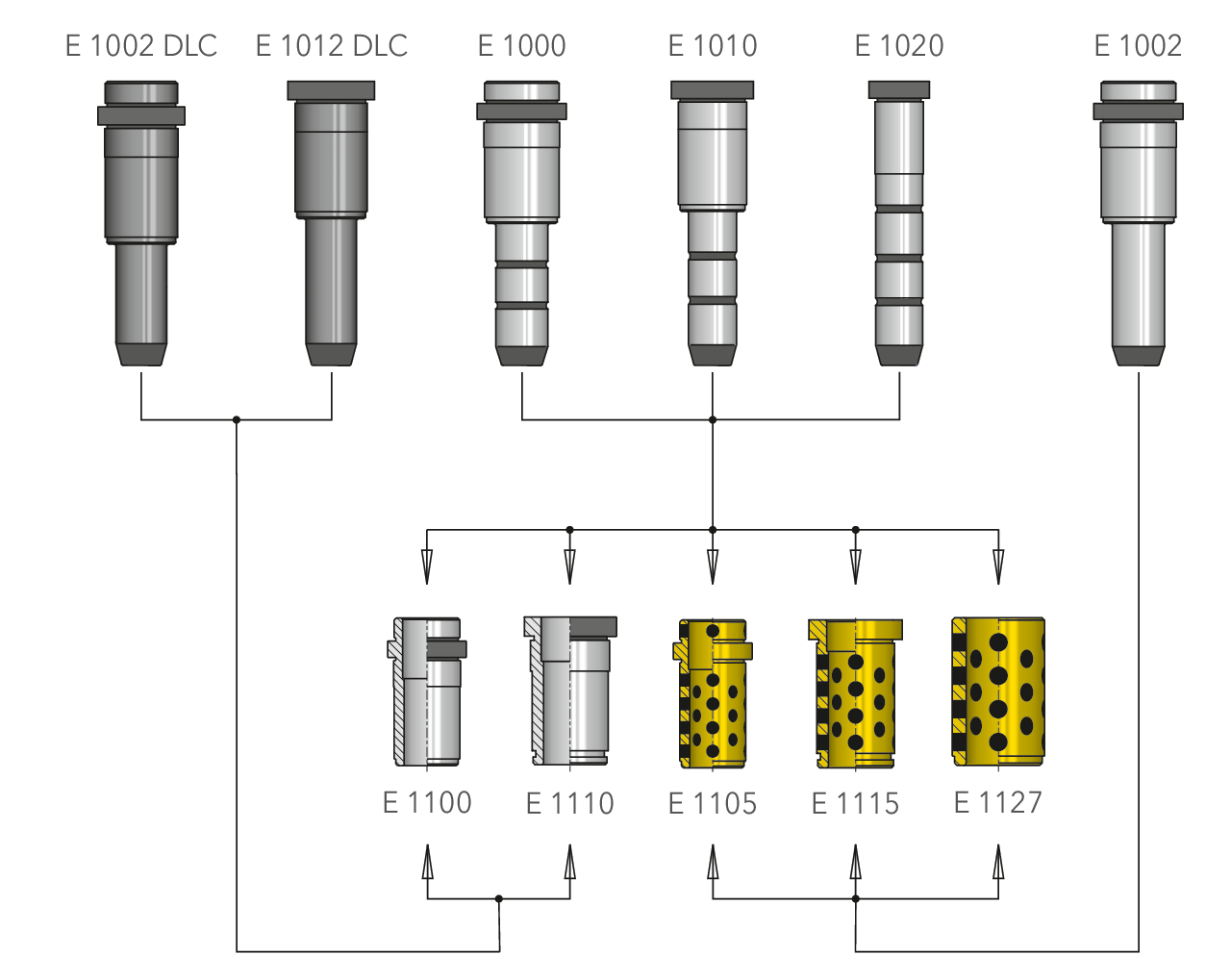

Standard guiding systems

The standard guiding system is used to guide the two mould halves. It essentially consists of guide pillars, guide bushes and centring sleeves.

The high-quality guiding elements match perfectly to our comprehensive range of cavity plates.

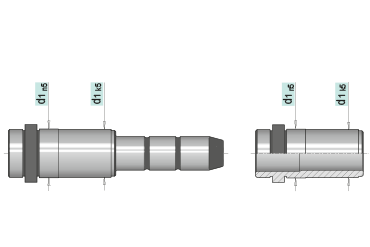

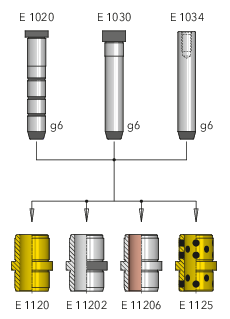

Guiding system with two fitting diameters

- Guiding system with two fitting diameters for an optimal fit in the guiding hole

- Second fitting diameter enables easy assembly and removal

Anti-rotation protection

The correct assembly of the mould halves is guaranteed by the ‘3 + 1’ principal. Three guiding elements with a large diameter and one guiding element with a smaller diameter are installed.

Mould bases designed in the Meusburger web shop have the 3 + 1 principle automatically.

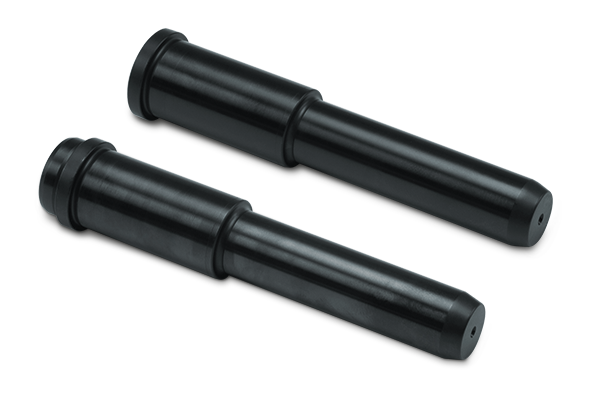

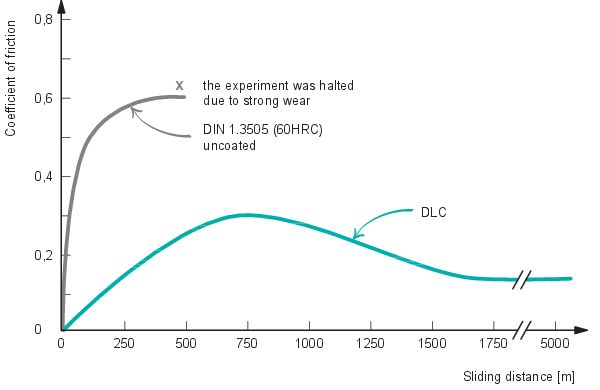

Guiding elements with DLC coating

- Increased corrosion resistance and service life

- Best dry-running properties enable use in cleanrooms

- Minimised wear thanks to excellent sliding properties

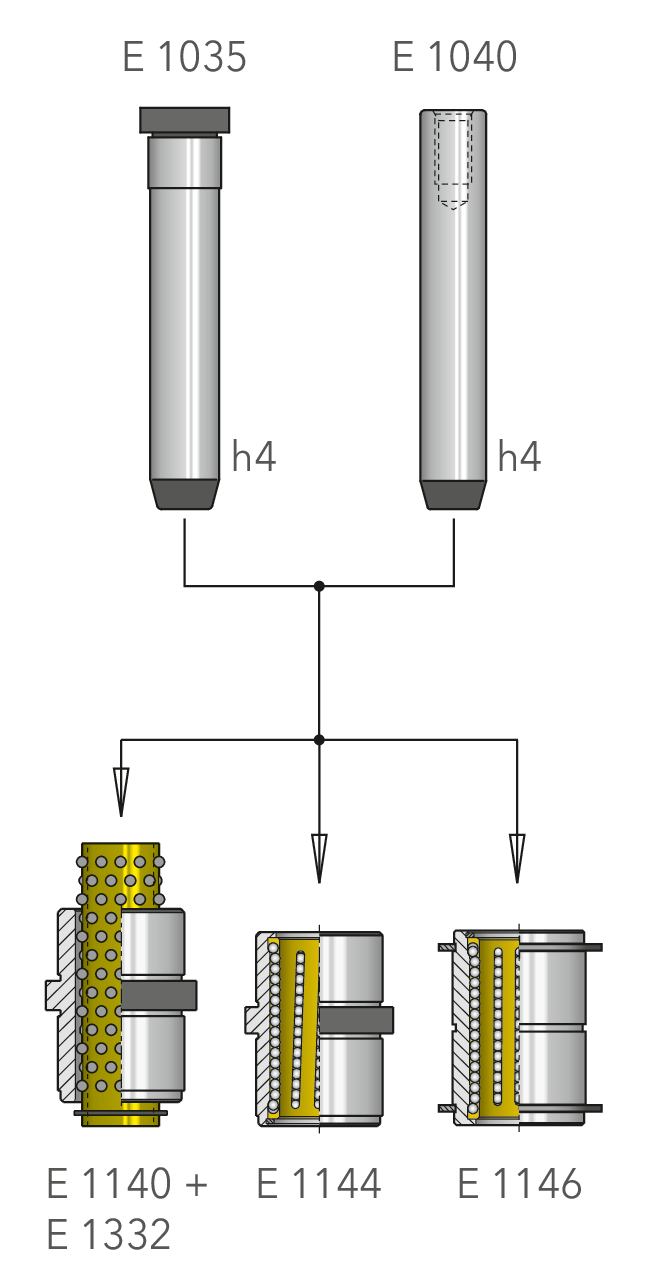

Ejector set guiding

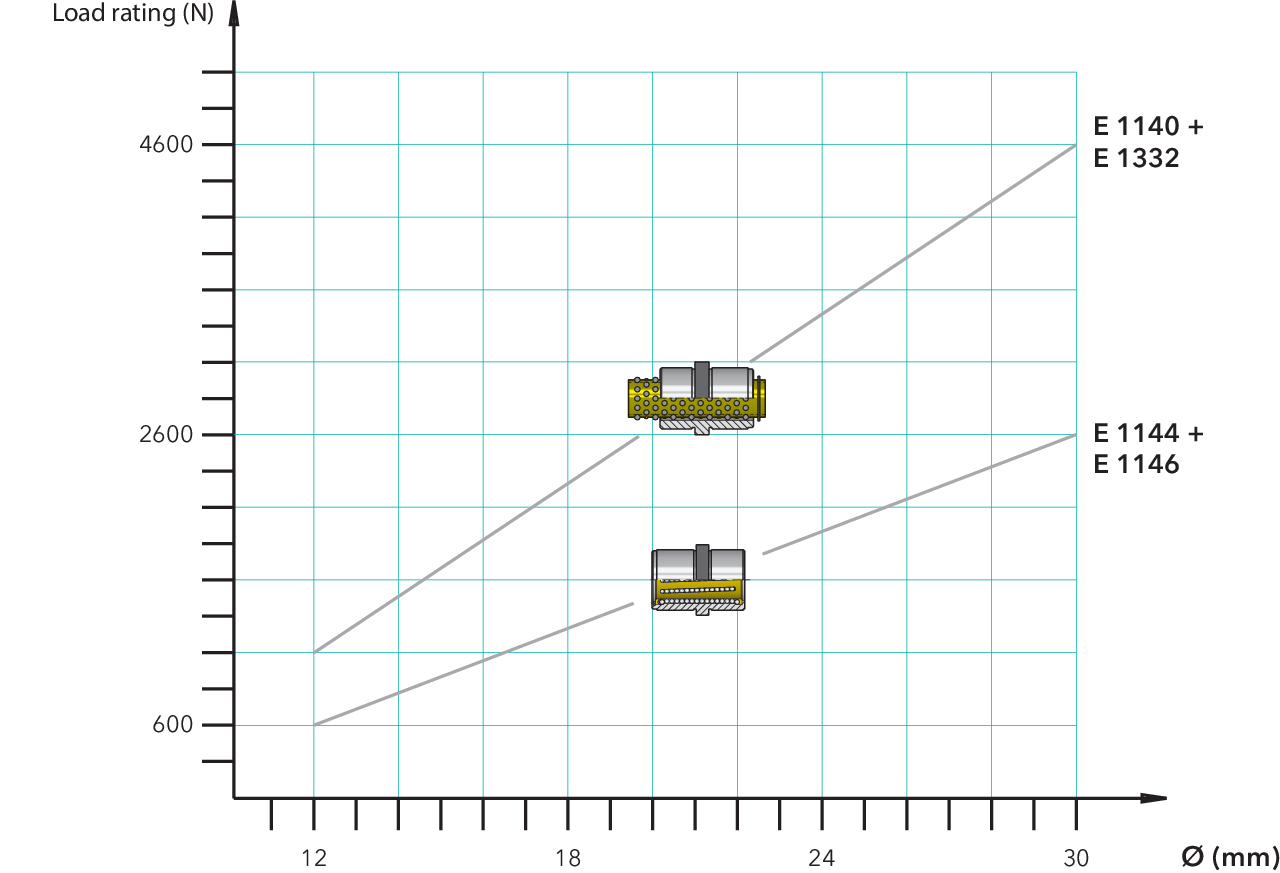

| NR | V * | FQ ** | Characteristics | Lubrication | |

|---|---|---|---|---|---|

| E 1144 E 1140 + E 1332 |  | high | low |

| VLS 250 high-performance oil |

| E 11206 |  | moderate | medium |

| Self-lubricating with VLS 250 high-performance oil |

| E 1120 |  | moderate | medium |

| VGS 180 High-performance grease |

| E 1125 |  | moderate | medium |

| Initially with VGM 160 High-performance grease |

| E 11202 |  | moderate | high |

| VGS 180 High-performance grease |

* V: Speed of ejector set during demoulding

** FQ: Permissible shear force

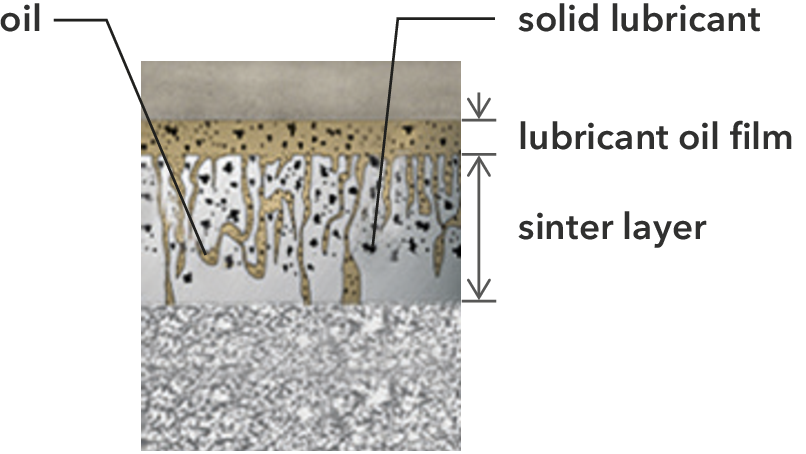

Sliding guide with self-lubricating sinter layer

- Ideal for self-lubricating applications thanks to the oil depot and solid lubricant MoS2 in the sinter layer

- The frictional heat causes the oil to rise to the sliding surface. Due to its capillary action the oil retreats back into the sinter layer (when the machine is idle).

- The ideal diffusion zone between the sinter layer and the steel sheath ensures inseparable molecular bonds

- High resistance to abrasive wear and very good emergency operating features without additional lubrication

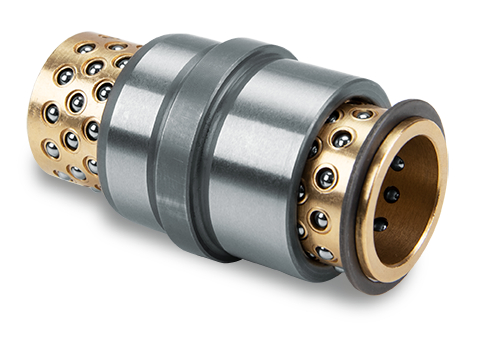

Ball guides – precise and smooth running

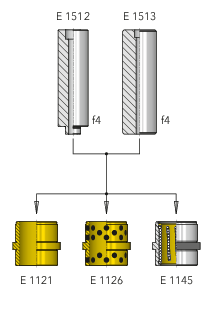

Flat guiding unit

- Vertical installation from the split line face

Advantage: machining of pocket and thread in one clamping operation - Horizontal installation from the side

Advantage: space-saving installation

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

© 2022 by Meusburger Georg GmbH & Co KG | All rights reserved

Česká republika [CS]

Česká republika [CS]

Danmark [DA]

Danmark [DA]

Deutschland [DE]

Deutschland [DE]

España [ES]

España [ES]

France [FR]

France [FR]

India [EN]

India [EN]

Italia [IT]

Italia [IT]

Magyarország [HU]

Magyarország [HU]

México [ES]

México [ES]

Nederland [NL]

Nederland [NL]

Polska [PL]

Polska [PL]

Portugal [PT]

Portugal [PT]

România [RO]

România [RO]

Schweiz [DE]

Schweiz [DE]

Slovenija [SL]

Slovenija [SL]

Srbija [SR]

Srbija [SR]

Suomi [FI]

Suomi [FI]

Sverige [SV]

Sverige [SV]

Türkiye [TR]

Türkiye [TR]

United Kingdom [EN]

United Kingdom [EN]

USA [EN]

USA [EN]

Österreich [DE]

Österreich [DE]

Ελλάδα [EL]

Ελλάδα [EL]

България [BG]

България [BG]

Росси́я [RU]

Росси́я [RU]

华 [ZH]

华 [ZH]